Automatic Production Line

Frame Saw Machine Fully Automatic Production Line

Welcome to Sanhe, a pioneer in the wood industry, where innovation and quality craftsmanship come together to redefine the future of timber processing. As experts in the field, we are proud to introduce our cutting-edge frame saw machines and automatic production lines that are revolutionizing the way large wood enterprises operate.

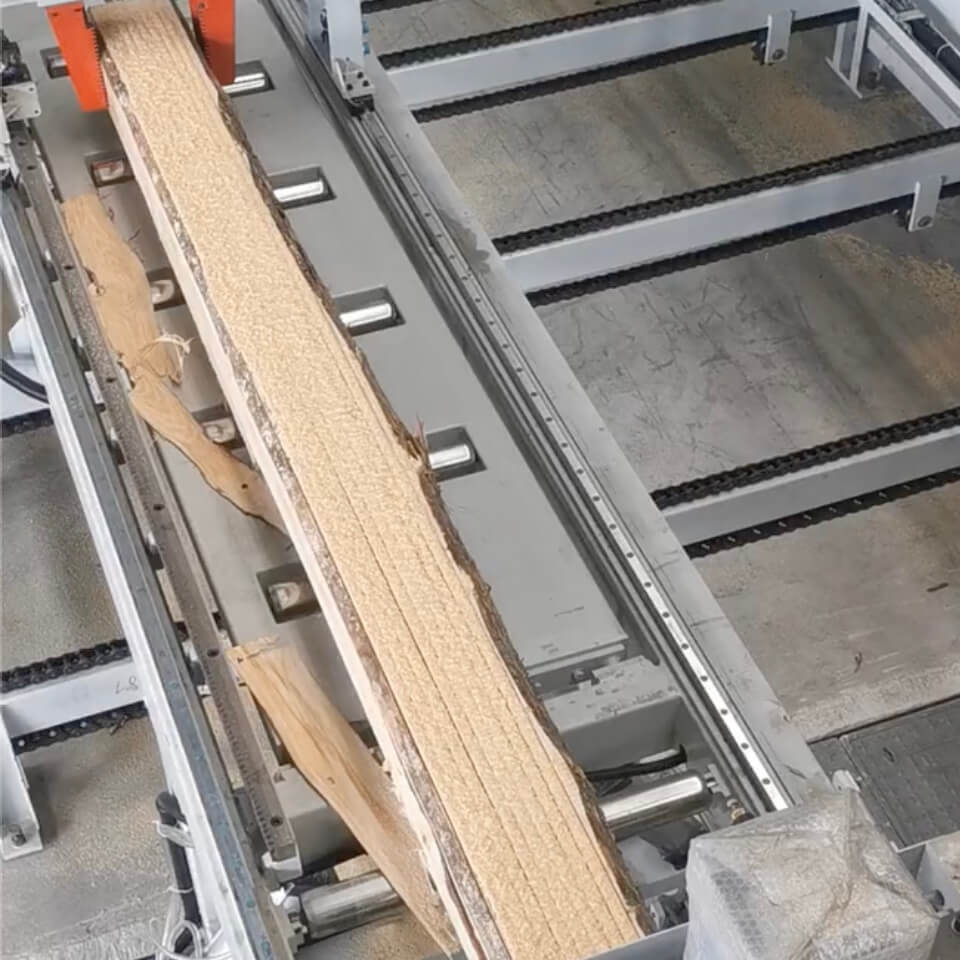

Our frame saws machines are equipped with multiple thin blades, allowing them to achieve remarkably smooth surfaces, making them ideal for veneer production. With their precision cutting capabilities, frame saws significantly reduce waste by up to 30% when cutting single veneer strips. This level of efficiency has made our frame saws particularly effective for medium and small-sized sawmills, enhancing their productivity and profitability.

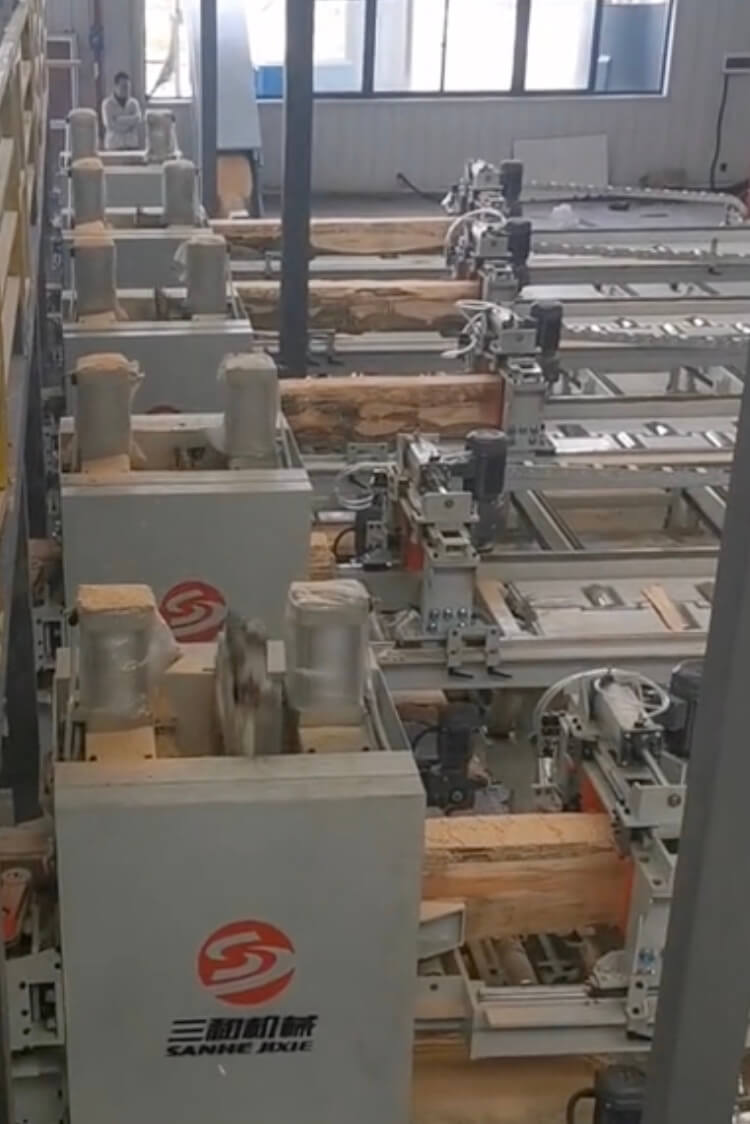

Recognizing the challenges faced by large-scale wood enterprises in implementing automation technology and managing complex processes, we took it upon ourselves to find a solution. Introducing China's first set of heavy-duty frame saw machine automatic production lines, a feat achieved through independent research and development. This comprehensive solution covers every aspect of the production process, from material loading and feeding to sawing and unloading – all fully automated. Our automatic production lines offer the perfect frame saw application solution for large wood enterprises, streamlining their operations and maximizing output.

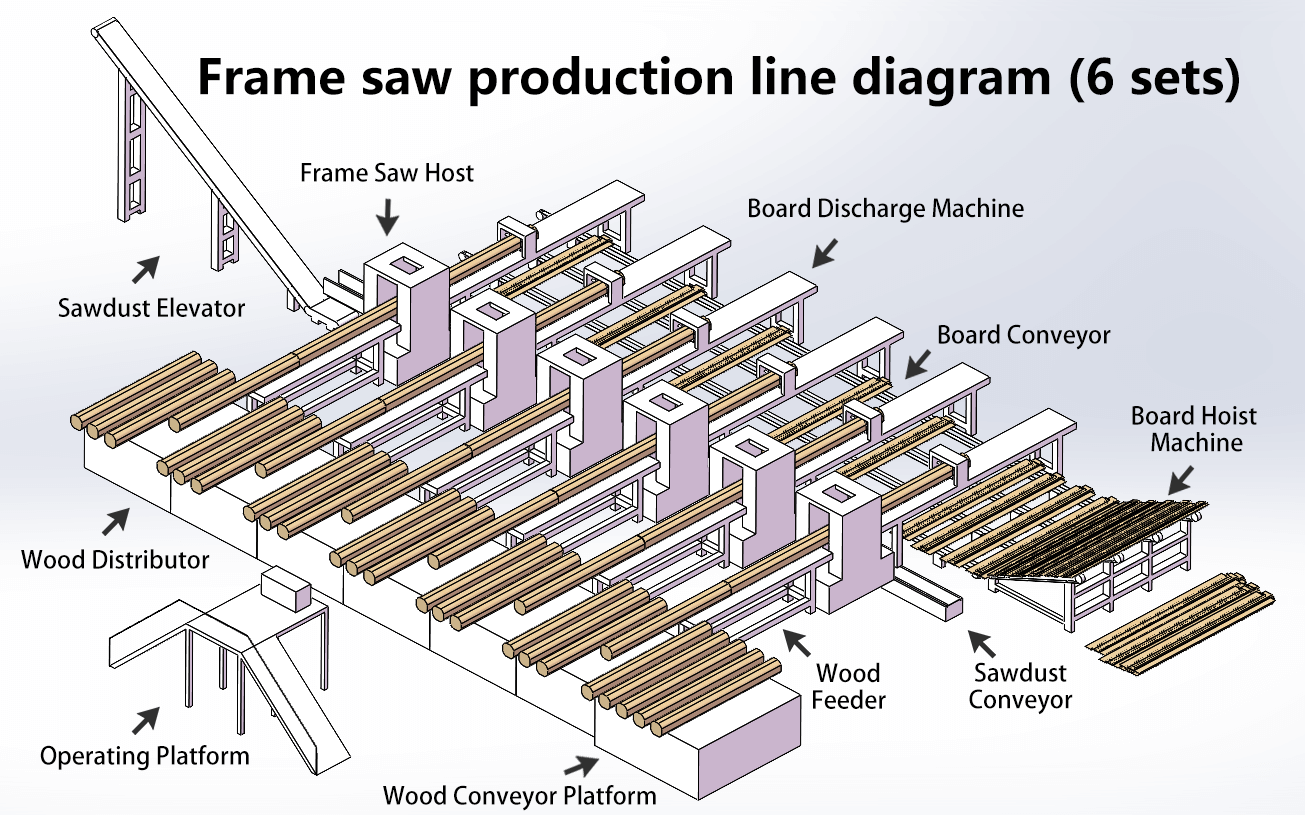

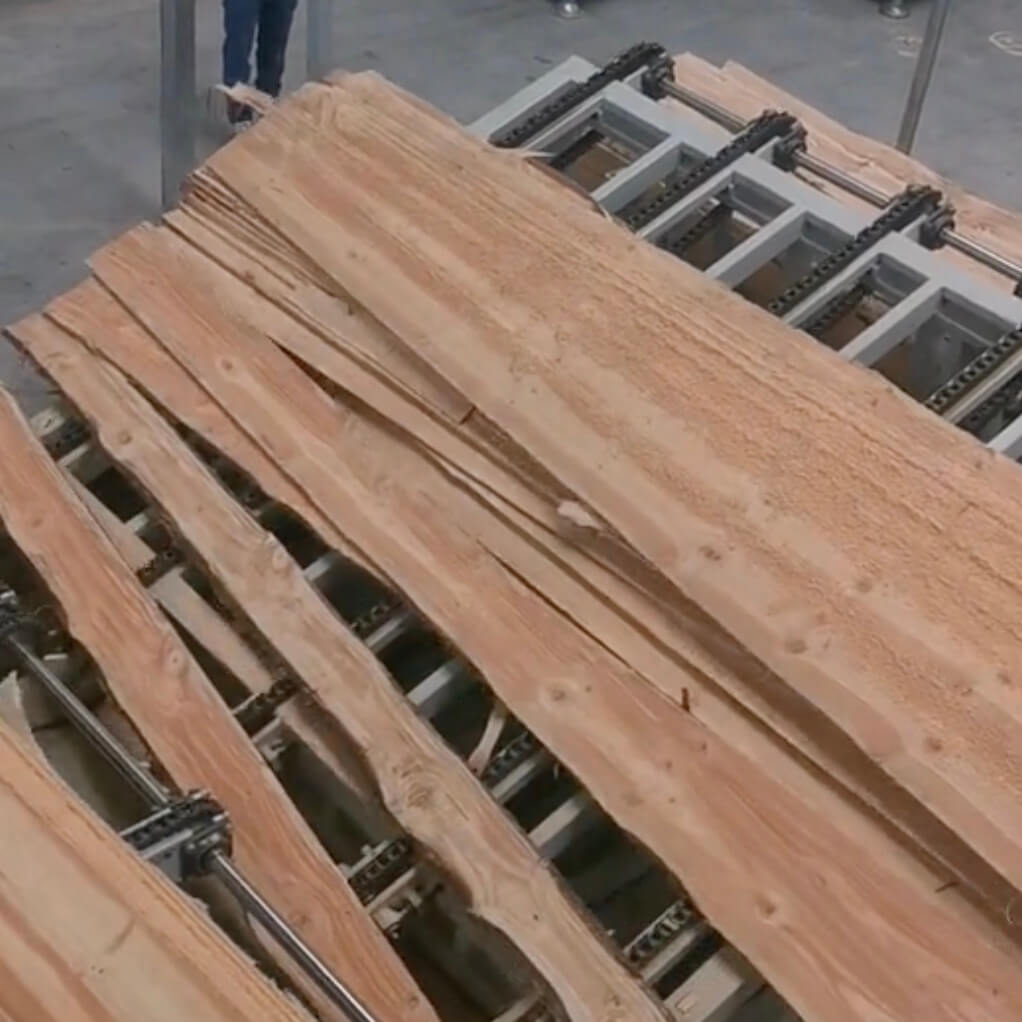

Our production line is comprised of six essential components: Wood Conveyor, Wood Divider, Frame Saw Machine Host, Wood Discharging Machine, Board Conveyor, Board Lifter, and Sawdust Conveyor. These elements work seamlessly together, allowing the production line, powered by six frame saws, to effortlessly cut over 22 cubic meters of timber within an 8-hour shift. The exceptional design and performance of our production line have earned it widespread acclaim and recognition among several major wood processing companies in China, solidifying our position as the industry leader.

With Sanhe's first frame saw machine automated production line launched in 2019, we are proud to share that it has been running flawlessly for four years, operating for 16 hours a day without a single failure – a testament to our unwavering commitment to excellence and quality. As the market leader in frame saw technology, we value our customers' feedback and actively incorporate it into our continuous improvement process, ensuring that our designs remain cutting-edge and perfectly aligned with real-world applications.

Our mission is to create premium, state-of-the-art frame saw machines that empower wood processing enterprises to thrive in the timber production industry. By fostering scalable development and driving innovation, we are dedicated to shaping a more efficient and sustainable future for the wood industry.

Thank you for choosing Sanhe – your trusted partner in transforming the way wood enterprises approach timber processing. Experience the difference with our innovative frame saw machines and automated production lines, engineered for excellence and reliability.

Structural Composition

| No | Device Name | Total Power(kw) | Machine Dimension(mm) | Weight(kg) |

|---|---|---|---|---|

| 1 | Wood Conveyor | 5.5 | 3000x2800x1100 | 2400 |

| 2 | Wood divider | 3.5 | 3000×2800x1100 | 2000 |

| 3 | Wood Feeder | 1.5 | 4300x1100x1100 | 850 |

| 4 | Frame Saw Host | 35.5 | 2300×1450×2300 | 5800 |

| 5 | Wood Discharging Machine | 1.5 | 6500×1100x1100 | 1500 |

| 6 | Board Conveyor | 5.5 | 3000×3300×500 | 650 |

| 7 | Board lifter | 3 | 3000×3300x1300 | 1850 |

| 8 | Sawdust Conveyor | 5.5 | 3000×500×500 | 350 |

SPECIFICATIONS

Our models include but are not limited to the following two types.

If you have special

requirements for the model, please feel free to further contact.